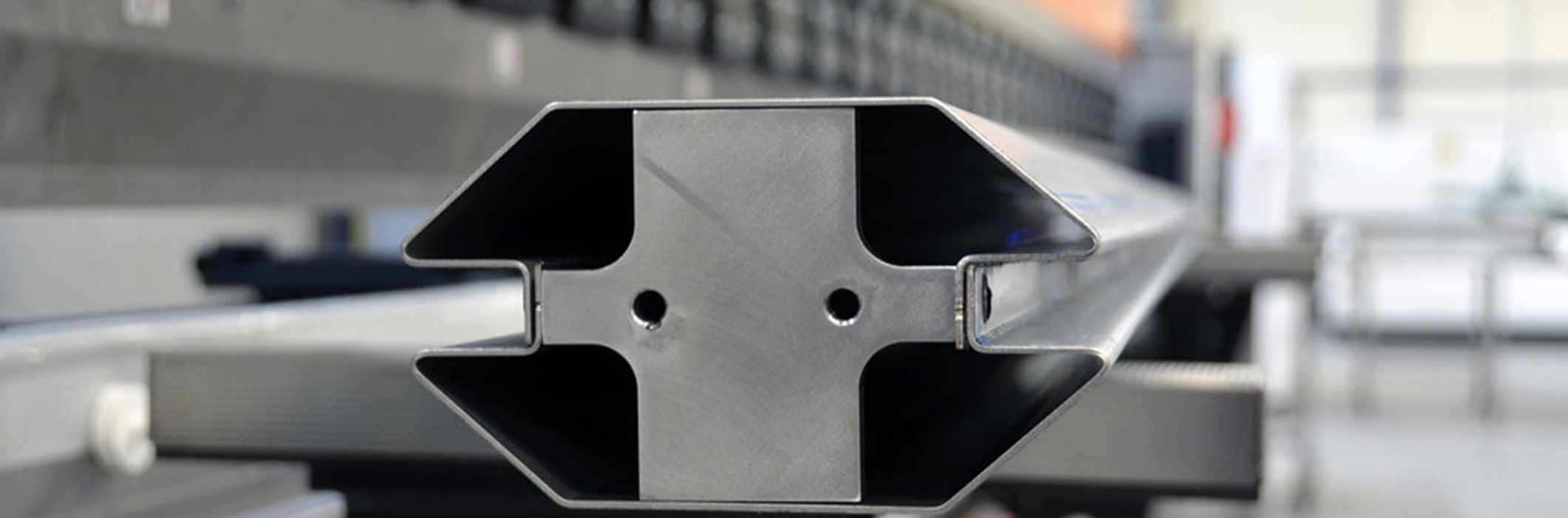

Customization in every industry

Paul Meijering has a very broad orientation in stainless steel and special alloys. End users purchase our materials, such as fittings and flanges, but also customized tubes and frames. We can do everything ourselves. Our strength is that we can serve customers very broadly, all tailor-made.

Own machine park

We serve a diversity of customers on all facets. We can do almost anything. Paul Meijering has a number of machines with which we can deliver customized work. Think of edging, cutting, setting, cutting, CNC turning, re-marking, packaging and more. A plasma cutting machine will soon be added to our machine park, so that we can continue to supply the increasing demand at the speed that we are used to.

Specific customization

Customers often come with a drawing with a specific question. We can digitally read that drawing and we can then deliver those products. We must be able to produce in accordance with the drawing and that is what customers can expect from us.

Consider, for example, customization for the food industry. For a bakery machine we then deliver the trays for production. For example, there are many more market segments in which Paul Meijering is active and for which customized stainless steel is supplied. Think of industries such as machine building, oil & gas, food industry, shipbuilding, installation technology.

Whatever challenge we encounter, together with the client we look for a solution.

Ensure quality

Paul Meijering, for example, supplies many heat-resistant pipes for installation technology customers. For example a 321-quality tube. For this market, this must be produced to a certain size in length, with different tolerances. Because we can do a lot in-house, we have control over the fast delivery and quality that we guarantee. In addition to supplying customized pipes, we now also receive the request for cutting through this customer. We find this just as important, because we strive for intensive cooperation with our customers.

Critical delivery times

Delivery time is often very critical and materials that are requested are not always standard. Materials often have to be produced to a certain size and obtained through external suppliers. We have been doing business closely for years with factories with which we have good experiences. We know this because we regularly audit them, make personal visits and maintain close contact with them. This way we keep the delivery time sharp.

Manual work

For a ship we have supplied dump tubes for fishing. This is a large diameter pipe that has been specially cut off by us. Customization for this is fairly accurate and specialized. The diameter is too large for completely automated work. This often requires manual work and machines must be set manually. Our employees are fully trained in this. Together we have managed to complete this to the complete satisfaction of the customer and we are now working on the next order in triplicate.

Sustainable cooperation

Ruud van de Mortel has been working at Paul Meijering for more than ten years and is responsible for the Customization department.

“We stand for long-term sustainable relationships. We have a fairly broad orientation in what we can deliver, so we can serve a huge number of markets. Whatever challenge we encounter, we look for a solution together with the customer. This also applies to our suppliers with whom we cooperate. We only do business with suppliers with whom we have good experiences. To create a solid foundation for both us and our customers. "