Incoloy 825 / UNS N08825 pipes

Incoloy 825 / UNS N08825 pipes

15 March 2018

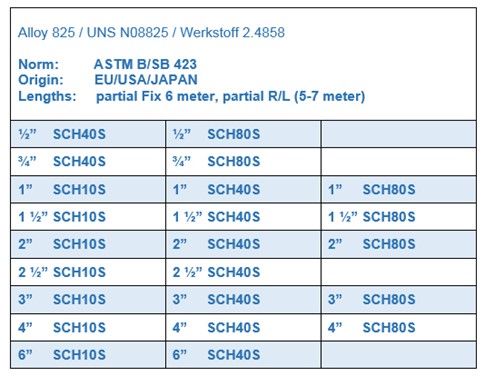

From mid-March, we are expanding our stock of seamless pipes. For Incoloy 825 / UNS N08825 you can also contact us. The following dimensions will soon be available from stock:

On demand SCH160 S can also be delivered.

Applications Incoloy 825

Referred to as “Nickel Alloy 825”, Incoloy 825 or UNS N08825 is a nickel-iron-chromium alloy with small amounts of molybdenum, copper, and titanium. This combination gives Incoloy 825 enhanced corrosion resistance in the harshest environments. The alloy is especially resistant to sulfuric and phosphoric acids / alkalis under both oxidising and reducing conditions.

Incoloy 825 offers a number of benefits:

• Excellent resistance to both reducing and oxidizing acids / alkalis like sulfuric and phosphoric

• Helps to avoid stress-corrosion cracking

• Stops localized attacks such as pitting and crevice corrosion

• High level of resistance to variety of oxidizing substances such as: sulphuric, sulphurous, phosphoric nitric / organic acid, nitrates, oxidizing salt and ammonium hydroxide.

Because of its superior corrosion resistance characteristics, Incoloy 825 is in use in a number of industries and applications including: chemical processing, pollution control, calorifiers, oil and gas recovery, hot vessels for food, water, and seawater, acid production, pickling tank heaters, tanks, and equipment, nuclear fuel reprocessing, radioactive waste handling and marine exhaust systems.

Like most of the Incoloy alloys, Incoloy 825 has a unique chemical composition which includes:

• Ni 38-46%

• Fe 22% min

• Cr 19-23.5%

• Mo 2.5-3.5%

• Cu 1.5-3%

• Mn 1% max

• Ti 0.6-1.2%

Questions about Incoloy 825?

Contact Ruud van de Mortel - our specialist in this field