Deburring & finishing

When types of metal are cold-worked, for example by laser cutting, burrs can form. In addition to making the product look better visually, for safety reasons it is often necessary to deburr and finish metal sheets or hollow sections. With our advanced machinery we ensure a perfect deburring of machined metals. Of course we always deburr stainless steel material that you purchase from us.

Our skilled employees are happy to tell you about the possibilities for deburring and finishing material.

Questions about deburring and finishing?

Renso Strating is happy to help you on your way.

Grindingmaster Timesavers 42 series 1350 WRb

Deburring, finishing and edging

We the Grindingmaster Timesavers 42 machine to deburr plates lasered on our BySmart fiber 4020 plate laser. The machine deburr your products with the best quality. This is achieved by a multi-rotating brush machine equipped with eight aggregates, which deburr evenly and round the edges of the metal. This makes it possible to create a rounding radius of up to 2 mm. We provide a premium finish for your product.

Specifications

Suitable for parts from 30 mm. Equipped with a multi-rotating brush machine and suitable for processing laser cut, dented, 3D and machined stainless steel materials. We save 50% of the time required for manual machining of laser cut parts with this machine.

Advantages: high quality and fast production | large variety of sheet thicknesses possible | deburring, rounding and finishing in one step

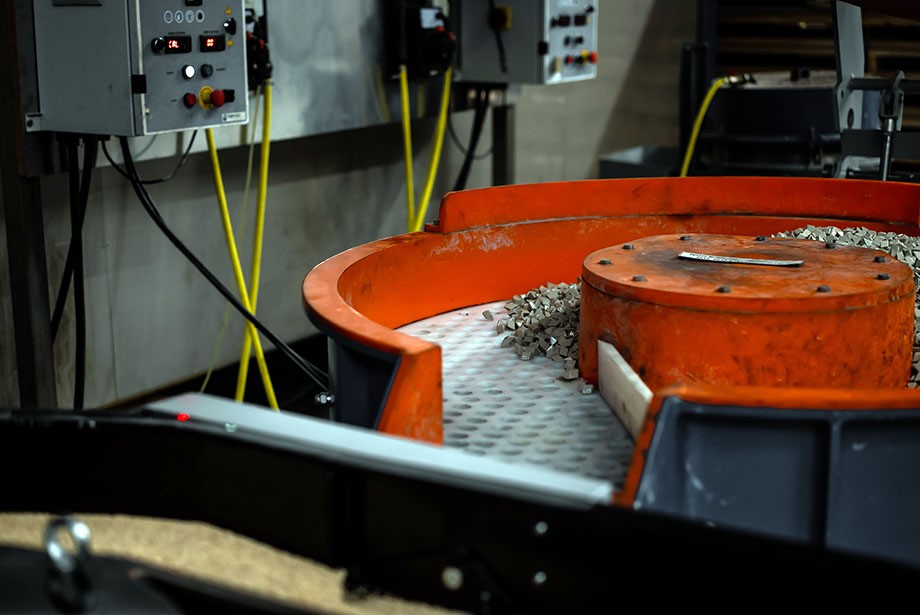

Vibromak VKUE500 and VKS50

We use a Vibromak VKUE500 and VKS50 for drumming and deburring semi-finished products. These machines are specifically used for vibration surface treatments, such as deburring, polishing, radii, oil cleaning, rust cleaning, oxide and polishing of metal and non-metal materials.

This system operates about 30% more powerfully than machines with a vibratory motor, enabling more efficient work in a shorter time. Suitable for: products up to 250 mm

Vibromak VKK 400 PN

The Vibromak VKK 400 PN - This vibrating dryer machine is used for drying the surface of wet finished parts. The Vibromak VKK 400 PN has heating elements in the bowl for heating corn pellets. The corn pellets are used to obtain a flawless and polished surface of the parts.

A burr-free product

Do you want to know more about the possibilities for sublime finishing of materials? Then contact one of our employees. They are happy to tell you more about deburring metals.