Laser cutting tubes

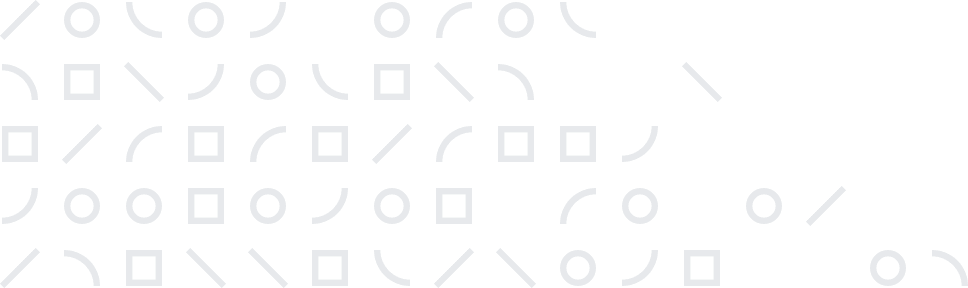

The BLM 3D LT8.20 fiber tube laser has the largest working range for laser tube cutting and has a 4 kW laser source.

We do laser tube cutting specifically for you.

With our BLM 3D LT8.20 tube laser, we quickly and accurately machine your materials with maximum quality. Our experts ensure that the machine cuts your materials in a 3D mode to the correct length and provides the machining you want. Finishing operations such as drilling and punching are unnecessary thanks to a sublime finish. Cutting dust is removed automatically, so that the cut comes out of the machine completely clean.

Our customization department will be happy to provide you with more information on all machining options.

BLM 3D LT8.20 fiber tube laser

With our advanced BLM 3D LT8.20 fiber tube laser, many operations are possible and we are productive in large and small series.

To cut large series quickly, the tubes are loaded sequentially without interruption. If an urgent job comes along, you can adjust the two loading units to the desired situation in no time. The running series is picked up again immediately afterwards by the machine.

For small series and frequent production changes, the machine automatically configures itself to allow continuous, uninterrupted production.

Click on the image to the left and watch the video.

Technical specifications operations

Our BLM 3D LT8.20 tube laser can machine the following diameters at a maximum length of 6500mm.

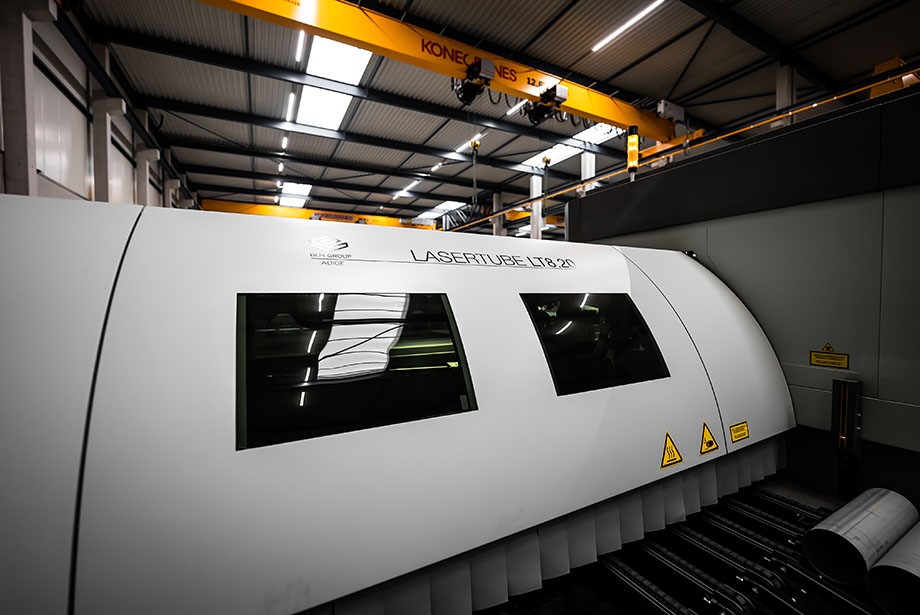

3D Models created with external CAD can be imported in STEP-, JGES-, XT- and even IFC-formats. Sales can only read STEP.

Process optimization

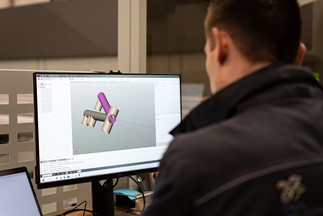

Saving starts with the material. By nesting as many pieces as possible from a tube, we save optimally on material and the final cutting waste is reduced.

Production changes without adjustments - When the product changes, the loader does not have to be operated manually each time. With a loading capacity of 5,000 kg, the machine operates completely autonomously for long periods of time. Loading the bundles is done quickly and without jamming, keeping the tube orientation intact.

Save time and material

Thanks to dynamic nesting, LT8.20 determines the sequence of parts to be cut from the tube to minimize cutting waste at the end of the tube and facilitate and speed up unloading.

Equipped with ArTube and ProTube CAD/CAM software for drawing, manipulating and designing tubular products. From idea to parts programme in a few simple clicks. ProTube provides reliable quotations and allows you to determine the best production strategy for both individual parts and complete production batches. Also checks system information, work in progress and estimated completion time.

Active Scan is an optical measurement system that uses real-time compensation to counteract axial errors caused by irregularly shaped tubes or profiles. Active Weld detects the position of the weld on the outside or inside and repositions the tube so that the weld is always at the programmed position.